Part 1

You should spend about 20 minutes on this task. Write at least 150 words.

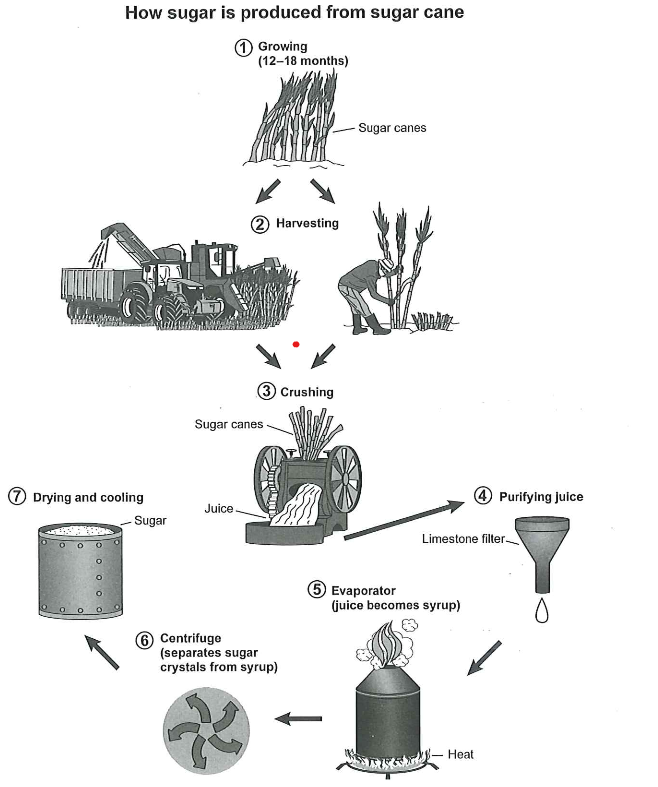

The diagram below shows the manufacturing process for making sugar from sugar cane.

Summarize the information by selecting and reporting the main features, and make comparisons where relevant.

Samples

Words: 0

Band 7.5

The diagram illustrates the complete procedure of making sugar from sugarcane.

Overall, the whole process of making sugar from sugarcane consists of seven stages.

The procedure starts from the growing of a plethora of sugarcane; it is a lengthy process and takes around one or one and a half years. In the next stage, all sugarcane will be harvested with special machines and experienced workers. In the third stage, sugarcane is put in another apparatus which sucks all the juice from it. Afterward, the juice is filtered through a limestone filter in order to separate any unwanted substances in the juice and purify it.

In the next stage, the juice is heated in a container on a very high flame to evaporate it; as a result, a refined syrup is made from that juice. After that, sugar crystals which were made in the syrup are separated by a centrifuge. At last, the sugar is placed in a separate container for drying and cooling so that it can be used by millions of individuals.

8.5

The flow chart illustrates the process of manufacturing sugar from sugarcane.

Overall, the whole process of making sugar from sugarcane is done in seven steps. The first step of the process is to grow a plethora of sugarcane, which is a lengthy process; it takes around 12 to 18 months. Then the farmer harvests all the sugarcane; after this stage is completed, harvested sugar canes are crushed with the help of a machine, which later sucks all the juices out of the sugar canes. To ensure the juices are pure, it goes through a filtration process, which purifies the juices.

By this stage, the pure cane juice is evaporated with the help of extreme heat until it becomes like a consistency. After that, the syrup is removed from the heat, and it is sent to be refined to ensure the sugars are separated from the syrup. At the very end of the process, the separated sugar crystals are dried and cooled, which results in the sugar that is consumed by billions of individuals every day.

The illustration showcases the stages of sugar production from sugar cane.

Overall, it is a seven-step, man-made, linear process. Sugar cane is used as a raw material and finally results in the sugar that is produced.

First of all, sugar cane, which grows for one or one and a half years, is harvested by specialized combines or workers. Next, the harvested crops are crushed and then squashed in a special apparatus to produce juice.

Following that, the juice is poured through a limestone filter to purify it from any precipitates and waste. After that, the purified sugar cane juice is heated in an evaporator, so that most of the juice evaporates and the rest becomes syrup. The syrup is then put into a centrifuge in order to extract sugar crystals by rapid rotation of the container. Finally, sugar crystals are transferred to special bins, wherein they are dried and cooled to become sugar.

9.0, IELTS Advantage guy’s structure

The diagram illustrates the production process of sugar made from sugar cane. Overall, the production of sugar from sugar cane includes seven steps. This process starts with farming of sugar cane plants and the further transforming processs of sugar cane juice into sugar.

Grown for about one year or one year and a half or so, the sugar canes are harvested by the harvesting machines or cut by farmers manually. These sugar canes, subsequently, are transported to the spots where thry are crushed up in the machines, through which the sugar cane juice is collected in the container and ready for later processes.

The juice then is purifyed using limestone filter, before it evaporates and becomes syrup after being heated in the oven. Centrifuges then separate sugar crustals from syrup, which is going to be collected into the cylinder. The sugar is eventually produced through drying and cooling.

The diagram illustrates the production process of sugar made from sugar cane.

Overall, the production of sugar from sugar cane included seven main stages. The process starts with farming of sugar cane plants, ends with drying and cooling down the final product: sugar. In general, the procedure can be divided into two board phases: the plantation of sugar canes and the production of sugar.

Initially, sugar cane plants are planted for a year and a half to become mature. After that period of time, they can be harvested by farming vehicles or by farmers manually with a blade. Then, they are transfered to the manufacturing plant for further production of sugar.

In the next phase, sugar canes were crushed by a crushing machine to produce juice that are subsequently sent through a limestone filler for purification. Syrup are manufactured from the purified juice through an evaporator heated from below. Ultimately, sugar is extracted from syrup by a centrifuge, then are dried and cooled down inside a container.

7

The diagram below shows the production method for making sugar from sugar cane.

Overall, it is evident that growing sugar cane involves different tasks and takes almost a year and a half. Much effort is needed for growing sugar cane, and sugar cane is mostly. ready in winter every year.

After growing sugar cane for 12-18 months, we harvest the sugar cane with a machine or with people, but machines are faster, so most

Then, we crush the sugar cane to make juice.

After obtaining the juice, we purify it with a limestone filter, After filtration is complete, the juice becomes syrup when we use a juice evaporator and apply heat.

Now, in the centrifuge, we separate sugar

7.5 bands

sugar from sugar cane. This is quite a long process, almost taking up to 2 years, and this is pure sugar creation. In the last step, we dry and cool the sugar to finalize the process and prepare it for use.

The diagram illustrates the production process of sugar, how sugar is made from suger cane.

Overall, the process consists of seven steps, from growing sugarcanes to drying and cooling sugar

Looking at the data in more detail, firstly, sugar cane is grown in the field which takes up to 12 to 18 months for growth. After that, the harvesting starts with the help of advanced machinery and labour. The next step is crushing, where the sugar canes are crushed in the machine and converted into juice foam. Moving on to the next stage, where the juice is put in the limestone filter, which purifies the juice. After purifying, the liquid was heated in the machine. This step is called evaporation, where the juice becomes syrup. Followed by, the centrifuge is used to separate sugar crystals from syrup. In the last and final step, the sugar is put in the big container where the sugar is dried and cooled.

The diagram displays information about the sugar making process from sugar cane.

Overall, there are total 8 stages in the entire processing. Initially, it begins with the sugar cane’s growth completion which takes 12 to 18 months. Then, there are two ways of harvesting: manually and by machine to prepare the sugar canes for further processing. Furthermore, the next stage is crushing the sugar canes in the machine to make juice and to make it more pure juice goes to filtering. In the fifth stage, juice thrown into big drums to heat them, during this process syrups go into evaporation and a centrifuge separates sugar crystals from syrup. Eventually, after drying and cooling sugar becomes ready for use.

To sum up, the procedure of sugar making goes through diverse stages; many things play a key role such as, land, farmers, machines, filters, heat or flame and other elements manufacturing sugar.

6 bands

The provided diagram illustrates the stages of sugar production from sugar cane.

Overall, the production of sugar from sugar cane is a linear process. The process involves 7 stages which begin with sugar cane cultivation, taking 1 to 1.5 years, and ends with the drying and cooling of the sugar crystals.

To begin, the process of making sucrose out of sugarcane begins with planting. It takes 12-18 months to mature then it is harvested mechanically or manually. Next is crushing the sugar cane to extract the juice from it.

Following that, the purifying stage is done by using a limestone filter to separate impurities. Thereafter, the juice is put in an evaporator and heated to form a syrup. Then, the syrup is placed in a centrifuge to separate sugar crystals from the syrup. Finally, the sugar crystals are poured into a container to dry and cool for packaging and distribution.

Band Score 9.0

The process diagram portrays the sugar manufacturing process by utilizing sugar canes. Overall, the process consists of seven steps, starting from the growing period, followed by harvesting, and finally leading to juice purification and crystal formation.

Firstly, sugar cane crops are grown, which usually take 12-18 months to fully mature. After a certain period, harvesting is done using mechanical methods or simply by hand. Then, crushing is performed using a machine to extract the sugar cane juice. In the next step, the juice is purified by passing it through limestone filters to remove dirt and debris, followed by heating in an evaporator to prepare concentrated syrup. Subsequently, the prepared syrup is transferred for the centrifugation process, where sugar crystals are separated from the syrup. In the final stage, the sugar crystals are exposed to drying and cooling processes, where sugar is prepared for packaging and delivery.

In general, the whole process follows a series of steps where careful extraction, purification, and centrifugation processes produce sugar, utilizing sugar cane.